Main technical parameters

| Items | Characteristics | ||||||||||

| Operating temperature range | -55℃--+105℃ | ||||||||||

| Rated voltage | 6.3--100V.DC | ||||||||||

| Capacitance tolerance | ±20%(25±2℃ 120Hz) | ||||||||||

| Leakage current(uA) | 6.3WV--100WV 1≤0.01CVor3uA Larger C:Nominal capacity(Uf) V:Rated voltage(V) Reading after 2 minutes | ||||||||||

| Loss angle tangent value (25±2℃ 120Hz) | Rated voltage(V) | 6.3 | 10 | 16 | 25 | 35 | 50 | 63 | 80 | 100 | |

| tg | 0.38 | 0.32 | 0.2 | 0.16 | 0.14 | 0.14 | 0.16 | 0.16 | 0.16 | ||

| If the nominal capacity exceeds 1000 uF, for each additional 1000 uF,loss angle tangent increased by 0.02 | |||||||||||

| Temperature characteristic (120Hz) | Rated voltage(V) | 6.3 | 10 | 16 | 25 | 35 | 50 | 63 | 80 | 100 | |

| Impedance ratio Z(-40℃)/ Z(20℃) | 10 | 10 | 6 | 6 | 4 | 4 | 6 | 6 | 6 | ||

| Durability | In an oven at 105 ℃, apply the rated voltage for a specified time, and then place it at room temperature for 16 hours before testing. The test temperature is 25± 2 ℃. The performance of the capacitor should meet the following requirements | ||||||||||

| Capacity change rate | Within ± 30% of the initial value | ||||||||||

| Loss angle tangent value | Below 300% of the specified value | ||||||||||

| Leakage current | Below the specified value | ||||||||||

| Load life | 6.3WV-100WV | 1000hours | |||||||||

| High temperature storage | Store at 105 ℃ for 1000 hours, and then test at room temperature for 16 hours. The test temperature is 25 ± 2 ℃. The performance of the capacitor should meet the following requirements | ||||||||||

| Capacity change rate | Within ± 30% of the initial value | ||||||||||

| Loss angle tangent value | Below 300% of the specified value | ||||||||||

| Leakage current | Below 200% of the specified value | ||||||||||

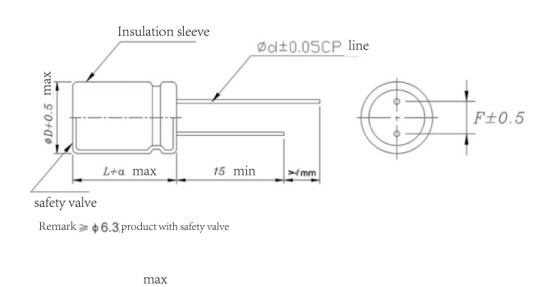

Product Dimensional Drawing

| D | 4 | 5 | 6.3 |

| L | 3.55 | 3.55 | 3.55 |

| d | 0.45 | 0.5(0.45) | 0.5(0.45) |

| F | 105 | 2.0 | 2.5 |

| α | +0/-0.5 | ||

Ripple current frequency correction coefficient

| Frequency(Hz) | 50 | 120 | 1K | ≥10K |

| coefficient | 0.70 | 1.00 | 1.37 | 1.50 |

Lead type aluminum electrolytic capacitor is a widely used electronic component, usually used to store charge and flow current, provide stable capacitance value as well as low impedance and low ESR value (equivalent series resistance), thereby improving the reliability of electronic products and performance stability. The following will introduce the application of lead type aluminum electrolytic capacitors in several important fields.

First, leaded aluminum electrolytic capacitors are widely used in electronic products. With the continuous development of technology and intelligence, various electronic products have become an indispensable part of consumers' lives in the market. Whether it is mobile phones, tablet computers in the field of mobile communications, or TVs, audio products and other products in the field of home entertainment, leaded aluminum electrolytic capacitors play a vital role. It can provide reliable capacitance value, low impedance and low ESR value, thus ensuring the performance stability and reliability of electronic products.

Second, leaded aluminum electrolytic capacitors are widely used in power supply circuits. Lead type aluminum electrolytic capacitors can provide stable voltage, and their high capacity and light weight make them widely used. In power supply circuits, leaded aluminum electrolytic capacitors can be used as a substitute for components such as inductors and voltage regulators to achieve stable power delivery and protect the long life of the power supply.

In addition, leaded aluminum electrolytic capacitors are also widely used in automotive circuits. In automotive circuits, due to the particularity of its working environment, it is necessary to use capacitors with high temperature tolerance and low electrical power factor. Leaded aluminum electrolytic capacitors can just meet these requirements, and at the same time have the advantages of compactness, lightness, and ease of use. In automotive circuits, leaded aluminum electrolytic capacitors are used in a wide range of applications, including engine ignition systems, car audio, and car lights.

Another important application area is energy storage and conversion. Leaded aluminum electrolytic capacitors serve as energy storage and energy converters in renewable energy device applications such as solar cells and wind energy cells. It has the characteristics of low loss and high efficiency, and it is playing an increasingly important role in the energy industry.

Finally, leaded aluminum electrolytic capacitors are also widely used in industrial control equipment. For example, it can be used in industrial power line motor operation control, electronic triggering systems, inverter protection, etc. In the industrial environment, lead-type aluminum electrolytic capacitors need to have the characteristics of high stability, heat resistance, vibration resistance, and interference resistance to ensure the high precision and stability of the control system.

To sum up, the lead type aluminum electrolytic capacitor is a widely used electronic component, and its application range is very wide. Whether it is in electronic products, or in the fields of automobile, energy, industrial control, etc., it can be seen. However, it should be noted that when choosing a leaded aluminum electrolytic capacitor, it must be selected according to the specific application environment and requirements.

| Voltage | 6.3 | 10 | 16 | 25 | 35 | 50 | ||||||

|

item volume(uF) |

measurement D*L(mm) | Ripple current (mA r.m.s/105℃ 120Hz) | measurement D*L(mm) | Ripple current (mA r.m.s/105℃ 120Hz) | measurement D*L(mm) | Ripple current (mA r.m.s/105℃ 120Hz) | measurement D*L(mm) | Ripple current (mA r.m.s/105℃ 120Hz) | measurement D*L(mm) | Ripple current (mA r.m.s/105℃ 120Hz) | measurement D*L(mm) | Ripple current (mA r.m.s/105℃ 120Hz) |

| 1 | 4*3.55 | 6 | ||||||||||

| 2.2 | 4*3.55 | 10 | ||||||||||

| 3.3 | 4*3.55 | 13 | ||||||||||

| 4.7 | 4*3.55 | 12 | 4*3.55 | 14 | 5*3.55 | 17 | ||||||

| 5.6 | 4*3.55 | 17 | ||||||||||

| 10 | 4*3.55 | 20 | 5*3.55 | 23 | ||||||||

| 10 | 4*3.55 | 17 | 5*3.55 | 21 | 5*3.55 | 23 | 6.3*3.55 | 27 | ||||

| 18 | 4*3.55 | 27 | 5*3.55 | 35 | ||||||||

| 22 | 6.3*3.55 | 58 | ||||||||||

| 22 | 4*3.55 | 20 | 5*3.55 | 25 | 5*3.55 | 27 | 6.3*3.55 | 35 | 6.3*3.55 | 38 | ||

| 33 | 4*3.55 | 34 | 5*3.55 | 44 | ||||||||

| 33 | 5*3.55 | 27 | 5*3.55 | 32 | 6.3*3.55 | 37 | 6.3*3.55 | 44 | ||||

| 39 | 6.3*3.55 | 68 | ||||||||||

| 47 | 4*3.55 | 34 | ||||||||||

| 47 | 5*3.55 | 34 | 6.3*3.55 | 42 | 6.3*3.55 | 46 | ||||||

| 56 | 5*3.55 | 54 | ||||||||||

| 68 | 4*3.55 | 34 | 6.3*3.55 | 68 | ||||||||

| 82 | 5*3.55 | 54 | ||||||||||

| 100 | 6.3*3.55 | 54 | 6.3*3.55 | 68 | ||||||||

| 120 | 5*3.55 | 54 | ||||||||||

| 180 | 6.3*3.55 | 68 | ||||||||||

| 220 | 6.3*3.55 | 68 | ||||||||||

| Voltage | 63 | 80 | 100 | |||

|

item volume(uF) |

measurement D*L(mm) | Ripple current (mA r.m.s/105℃ 120Hz) | measurement D*L(mm) | Ripple current (mA r.m.s/105℃ 120Hz) | measurement D*L(mm) | Ripple current (mA r.m.s/105℃ 120Hz) |

| 1.2 | 4*3.55 | 7 | ||||

| 1.8 | 4*3.55 | 10 | ||||

| 2.2 | 5*3.55 | 10 | ||||

| 3.3 | 4*3.55 | 13 | ||||

| 3.9 | 5*3.55 | 16 | 6.3*3.55 | 17 | ||

| 5.6 | 5*3.55 | 17 | ||||

| 6.8 | 6.3*3.55 | 22 | ||||

| 10 | 6.3*3.55 | 27 | ||||

-

Radial Lead type Miniature Aluminum Electrolyti...

-

Radial Lead Type Miniature Aluminum Electrolyti...

-

Lead type miniature type Aluminum Electrolytic ...

-

Chip Miniature Type Aluminum Electrolytic Capac...

-

Snap-in large type aluminum electrolytic capaci...

-

Radial Lead Type Miniature Aluminum Electrolyti...